In pharma and biopharma facilities, downtime is money. Every extra day a system is offline, production slows, schedules slip, and costs rise. That’s why forward-thinking engineering teams are turning to digital twins — and why Premech has made them central to our approach.

What Is a Digital Twin?

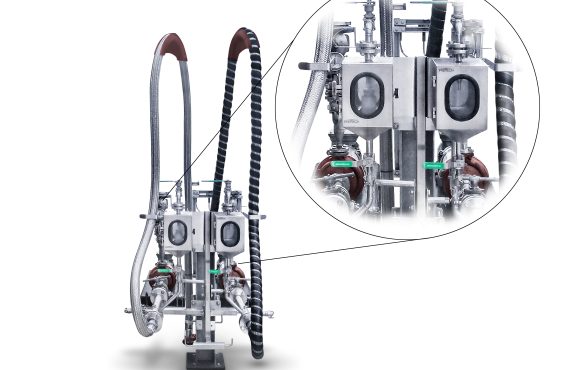

A digital twin is a live, 3D model of your facility, built using advanced scanning and modelling tools. It doesn’t just capture the walls, ceilings, and floors — it records pipework, cable trays, and access routes with millimetre accuracy.

Unlike static 2D drawings, a digital twin evolves with your site. Every change, upgrade, or retrofit can be mapped into the model, so you’re always working from reality, not assumption.

Faster Design, Smarter Decisions

With a digital twin, we can:

- Overlay vendor equipment models directly into your site layout.

- Simulate installation sequences months before delivery.

- Spot clashes digitally, rather than on install day.

- Engage stakeholders with clear, immersive walkthroughs.

This isn’t just engineering — it’s risk reduction. Problems are solved before fabrication begins, which keeps projects on schedule.

From Scan to Install

At Premech, we don’t stop at scanning. Our integrated design–fabrication–installation process means:

- The same team that scans your facility develops the design.

- The same team that models the skid fabricates it in-house.

- The same team that installs already knows every clash, anchor point, and access route.

No handovers. No disconnects. Just a clear path from digital to physical.

The Pharma Advantage

For project engineers and managers in highly regulated industries, digital twins offer:

- Traceability — a permanent 3D record for compliance.

- Faster approvals — visual models accelerate sign-off.

- Confidence — reduced risk, reduced downtime, better safety.

Future-Proofing Your Facility

Digital twins don’t just solve today’s project challenges — they lay the foundation for tomorrow’s upgrades. When your facility evolves, the model evolves too.

At Premech, we’ve seen how this technology transforms projects: less guesswork, more certainty, faster delivery.

Because in pharma, precision isn’t optional. It’s the difference between disruption and smooth operation.