In high-stakes pharmaceutical manufacturing environments, safety and efficiency are non-negotiable. When a mid-sized global biopharmaceutical company approached Premech to help solve a recurring safety risk during their IPA (Isopropyl Alcohol) unloading process, our team was ready to deliver a solution that was both practical and customised to their precise needs.

Risky Sampling Process from Tankers

Operators were required to manually collect samples from a platform above the tanker during IPA deliveries, a process repeated frequently and fraught with risk. With operator safety, workflow efficiency, and hygiene compliance in mind, the client sought a safer, faster, and more ergonomic way to sample IPA from the tanker.

A Familiar Problem, A Custom Solution

Drawing on previous experience with similar systems, Premech presented an initial concept showing how we had previously addressed comparable challenges. Recognising the relevance and our proven expertise, the client quickly greenlit the project.

We then carried out a comprehensive site survey to assess space limitations and any potential clashes with existing pipework. This allowed us to propose a fully integrated, custom solution that worked within the physical constraints of the site.

A Smart Sampling System

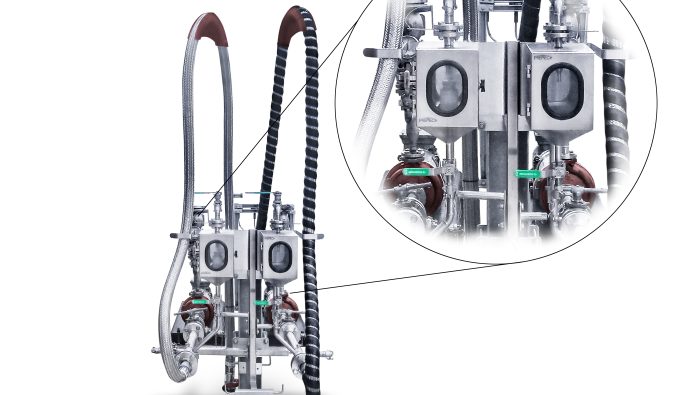

The final design featured a custom-built sampling spool system with flanged connections to fit seamlessly between the tanker and the plant’s existing transfer lines. It was designed using client specified piping materials, ensuring full compatibility with their operational standards.

A key feature was an in-line sampling box which eliminated the need for personnel to climb onto the platform above the tanker. The ergonomic design allowed the operator to draw a sample via a secure, accessible valve using a simple lever action. Once validated, the product could then be safely released through pumps for full unloading.

The new system was:

- Free-draining, ensuring no residue or trapped product.

- Operator-friendly, with safe access at ground level.

- Designed for minimal disruption, requiring only a single connection to the tanker.

An existing vertical pillar identified during the survey needed to be relocated, a challenge seamlessly addressed through proactive communication between the client and Premech’s engineers.

Precision Engineering in Practice

The result was a fully compliant, client-specific solution that:

- Enhanced operator safety

- Reduced unloading time

- Improved sampling accuracy

- Was installed and tested with minimal downtime

After successful SAT testing, the system was documented with a complete ETOP ensuring full traceability of materials and design decisions, vital for GMP compliance.

This project is a testament to Premech’s commitment to precision engineering and practical innovation. We don’t just build systems, we build better ways of working. By listening carefully, leveraging experience, and delivering to the highest quality standards, Premech continues to help pharmaceutical manufacturers evolve safely and efficiently.