Project Details

A large scale manufacturing complex embarked on a critical upgrade of an antiquated steam boiler within its boiler house. To allow this to happen, the significant task of removing old boilers and replacing them with a new energy efficient boiler was required. The uninterrupted operation of the remaining boilers was essential for the factories’ productivity.

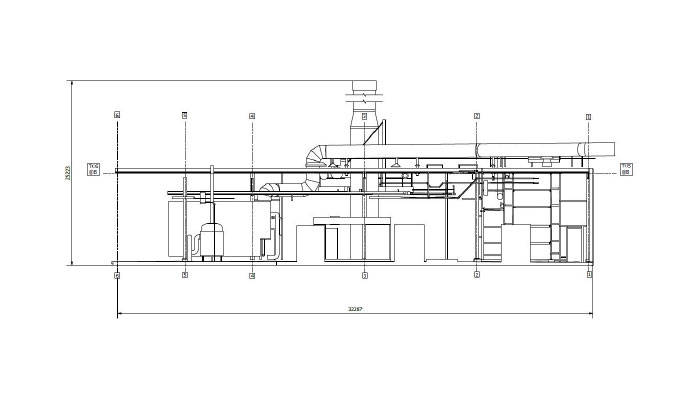

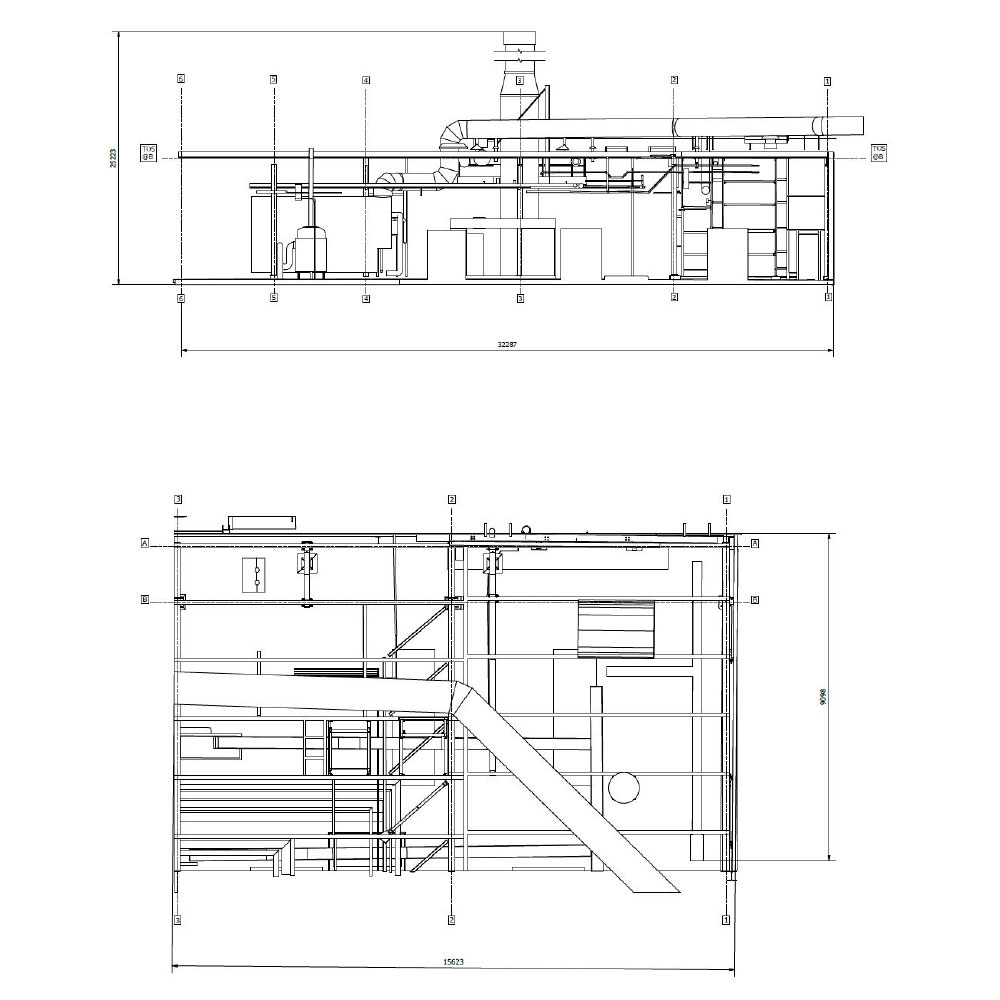

The network catered to five boilers, with two in operation, one under replacement, and another slated for decommissioning. Identifying the planned services to be decommissioned was crucial to repurpose the space for the new boiler’s services. In addition, the existing facility was barely sufficient to meet the space requirements for the new boiler due to it’s large size, the building’s structure required alterations for the new boiler’s installation.

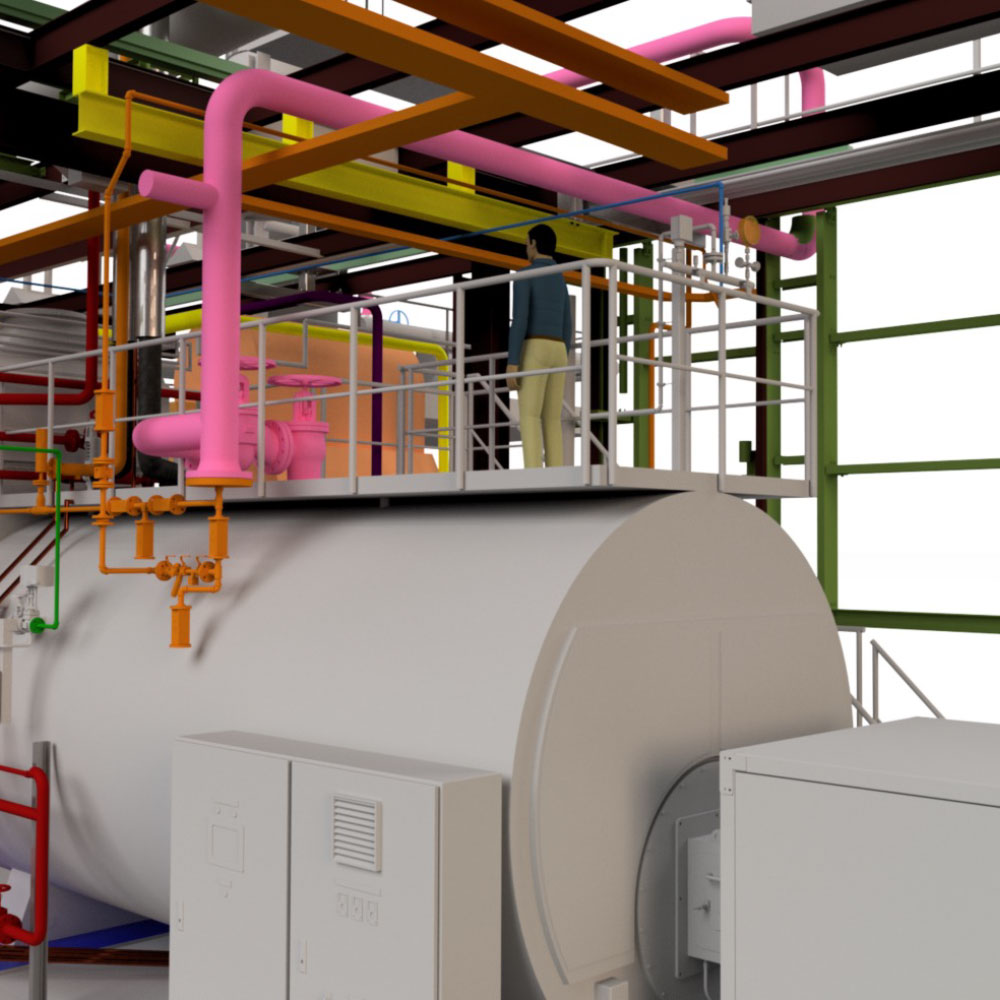

Premech commenced with a comprehensive 3D scan of the entire building, both inside and out. This facilitated the precise modelling of all current services and the identification of external tie-in points (Exhaust Flue, Cold Water Feed, Steam Out). Obsolete services were identified, revealing potential pathways for new routes. The boiler vendor’s STEP file was integrated into the model, enabling the design of new service routes and necessary structural modifications for boiler entry. Detailed schematics were then distributed to vendors, ensuring off-site fabrication of piping and structural modifications. without interference with existing infrastructure, months ahead of the planned install date.

Constructing a complete model before fabrication initiated a collaborative review process, allowing stakeholders have input on various design elements, leading to optimized results. Distributing the drawings to vendors expedited the fabrication of all structural steel changes and significant piping spools for the commissioning of the boiler, thus fast-tracking the project’s timeline.