Project Details

A global leader in the production of innovative medicines, our client is constantly looking for opportunities to increase safety and productivity in its manufacturing facilities. Operating a multi-floor facility layout, the upper floors are dedicated to materials handling and blending with the lower level given over to tabletting and packing.

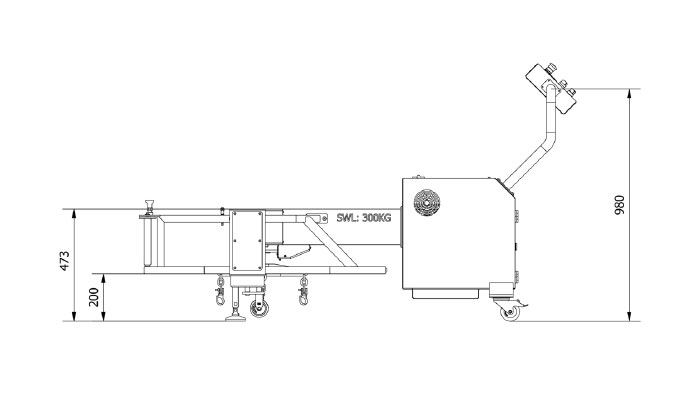

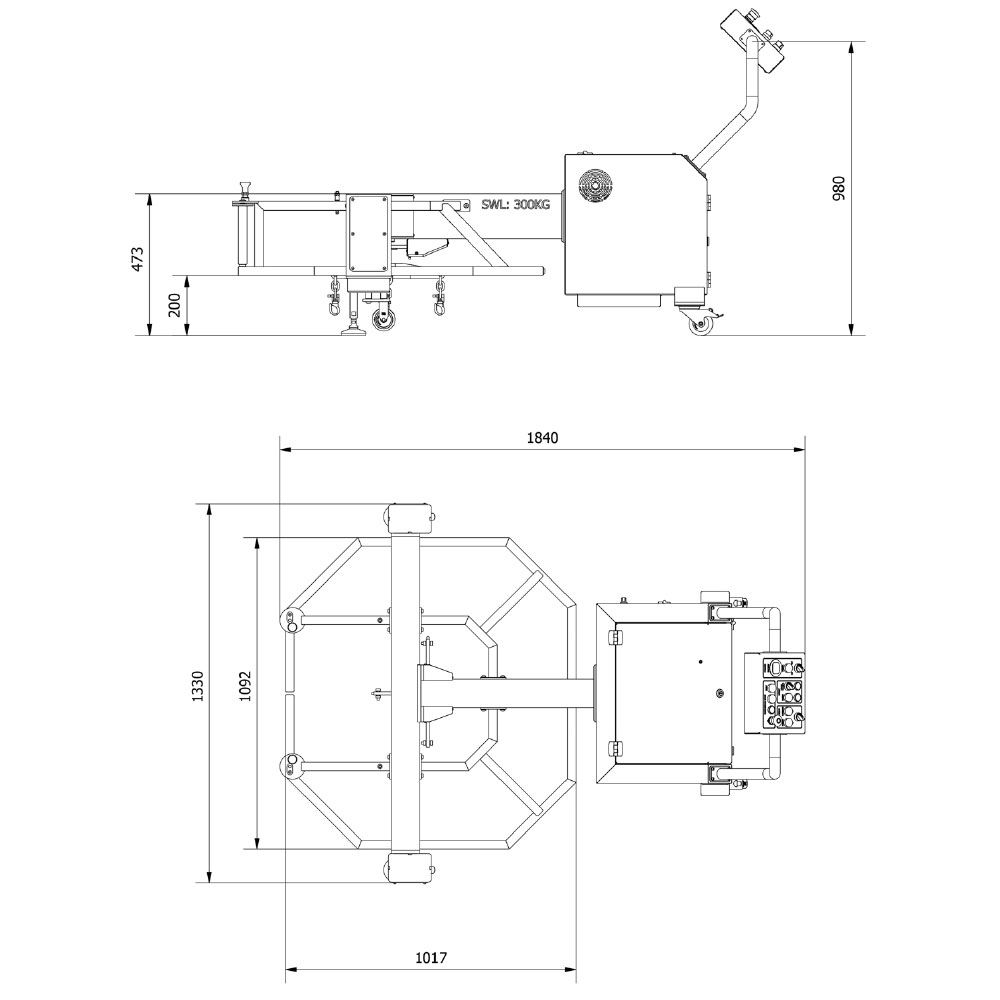

In a large tableting plant, cleaning turnaround time between batches has a significant bearing on production capacity. There is also the inherent safety risk of working at height when removing equipment between floors for cleaning. With that in mind, we were asked to design a solution to reduce the time required to remove the equipment from its docking position between floor levels, as well as the associated safety risk of working at height during the operation.

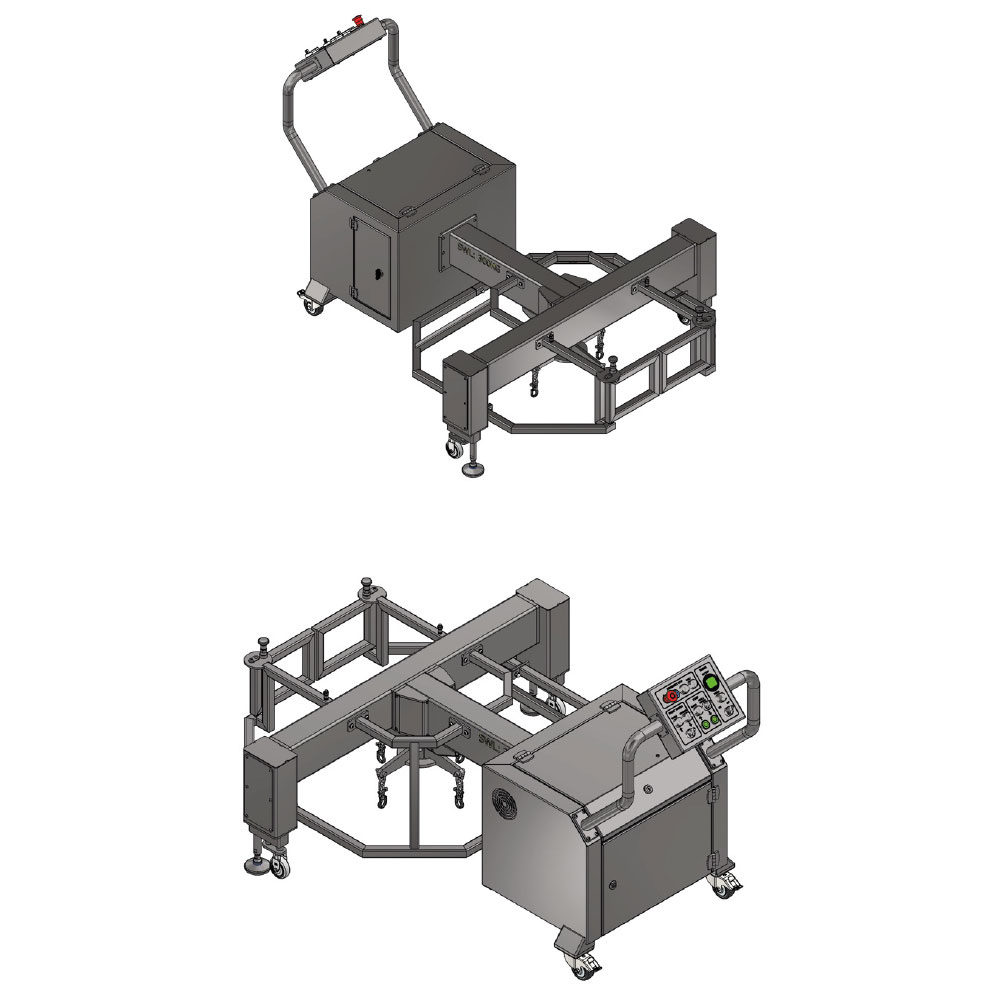

Embracing the challenge, we were aware the key to this project was understanding the process of the cleaning cycle and therefore engaged with all project stakeholders including facilities managers, engineers and operators alike. Once the process was understood and all the relevant areas identified, we set about 3D scanning all locations to ensure that all existing equipment was included in the initial design.

Aware that close client engagement was critical to the success of the project, a concept design was developed and demonstrated to the end users of the machine using our VR Headset. This enabled our clients to see with their own eyes how the machine would work and get a feel for how manoeuvrable it would be in tight areas.

The successful commissioning of two equipment hoists in this facility was hugely beneficial. Firstly, the working at height risk was completely eliminated due to the innovative design where the hoist, when in use, docks directly over the temporarily open floor. This means that with the inclusion of some carefully designed machine guarding, the operator cannot be exposed to a potential fall through the temporary opening.

Secondly, the entire process of removing the equipment for cleaning can now be carried out by a single operator. They can complete all the connection tasks on the first floor and then operate the hoist using remote control from the ground floor to monitor the equipment being lowered to an awaiting trolley positioned by the same operator.

The results have been clear to see – improved safety, reduction in cleaning turnaround time and reduction in the number of operators required.