Project Details

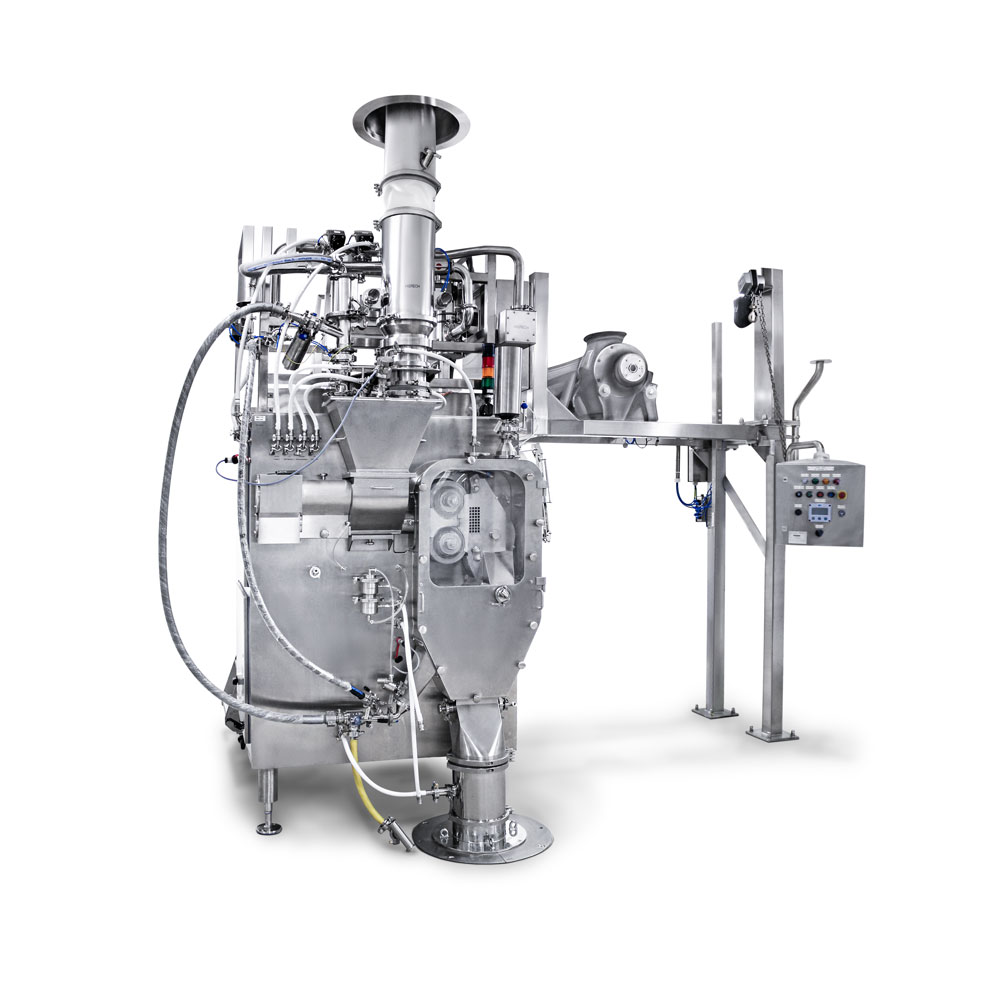

The client is an international project delivery specialist. They engaged us to provide an end-to-end design, fabrication and installation service for a new process line within an existing pharmaceutical plant. They were keen to leverage our expertise in 3D scanning technology, 3D design, in-house fabrication and cGMP installation to contribute to the delivery of a new compaction machine into a live pharmaceutical plant.

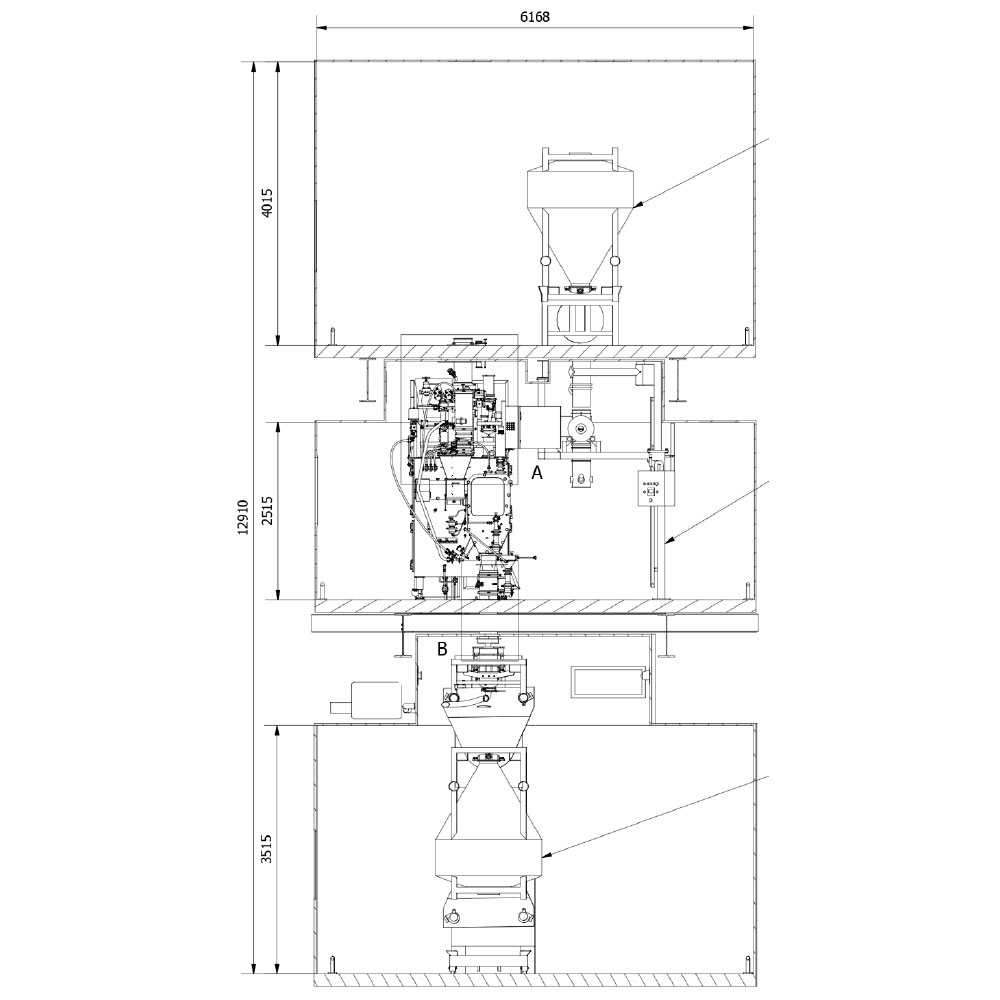

To increase the production capacity of an existing facility, a multi-floor powder compacting system was to be installed alongside an existing process. Due to tight time constraints during the upcoming installation period, it was critical that all ancillary equipment supporting the new machine were designed and manufactured ahead of install. Working closely with our client, we were keen to make the best use possible of the six-month lead time that comes with most new pharmaceutical machinery.

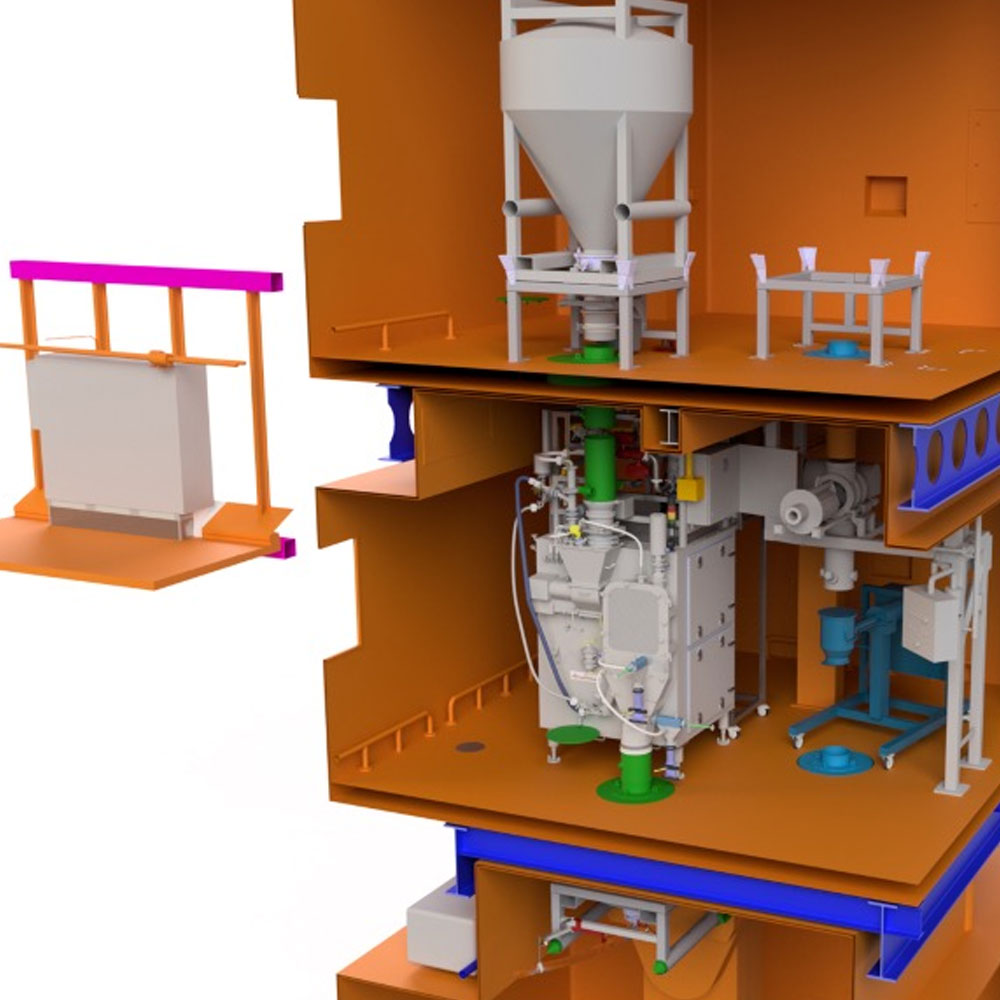

Beginning with the 3D scanning and modelling of the existing facilities, we were able to develop a full BIM model including every item that was present in room and applied the same detail to adjacent technical space which supported the cleanroom. We then incorporated the 3D model of the new machine into the BIM model and immediately started to work through the challenges of redesigning the existing processes and developing the mechanical support system for the new equipment.

As the project progressed, we engaged with the client on a weekly basis to solve problems and advance the design on as many work fronts as possible. Operating in the same design office, our BIM engineers were able to handover approved sections of the design to our fabrication design engineers and experienced fabricators who were then able to progress many ancillary equipment components into production months before the delivery date. In all, there were 37 different manufacturing packages ranging from powder transfer chutes, bespoke access platforms, machinery support frames, assembly stations and various modifications to existing equipment to support the safe operation of the new process.