Project Details

A mid-sized global biopharmaceutical company manufacturing active pharmaceutical ingredients (APIs) for use in medicines.

During unloading of IPA (Isopropyl alcohol) from tankers to holding tanks onsite, the operator must climb onto the tanker and take multiple samples for analysis. Due to the frequency of deliveries and the dangers to operators involved, the client asked us to develop a solution.

We had previously designed a similar version of the required system which we showed to the client outlining the physical connections and various mechanics. They recognised the similarity and our experience and were happy to engage us on the project. We carried out an extensive site survey to ascertain if there were any clashes with existing pipework.

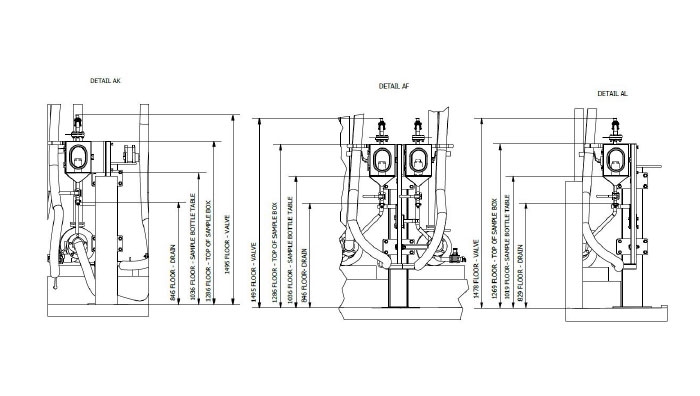

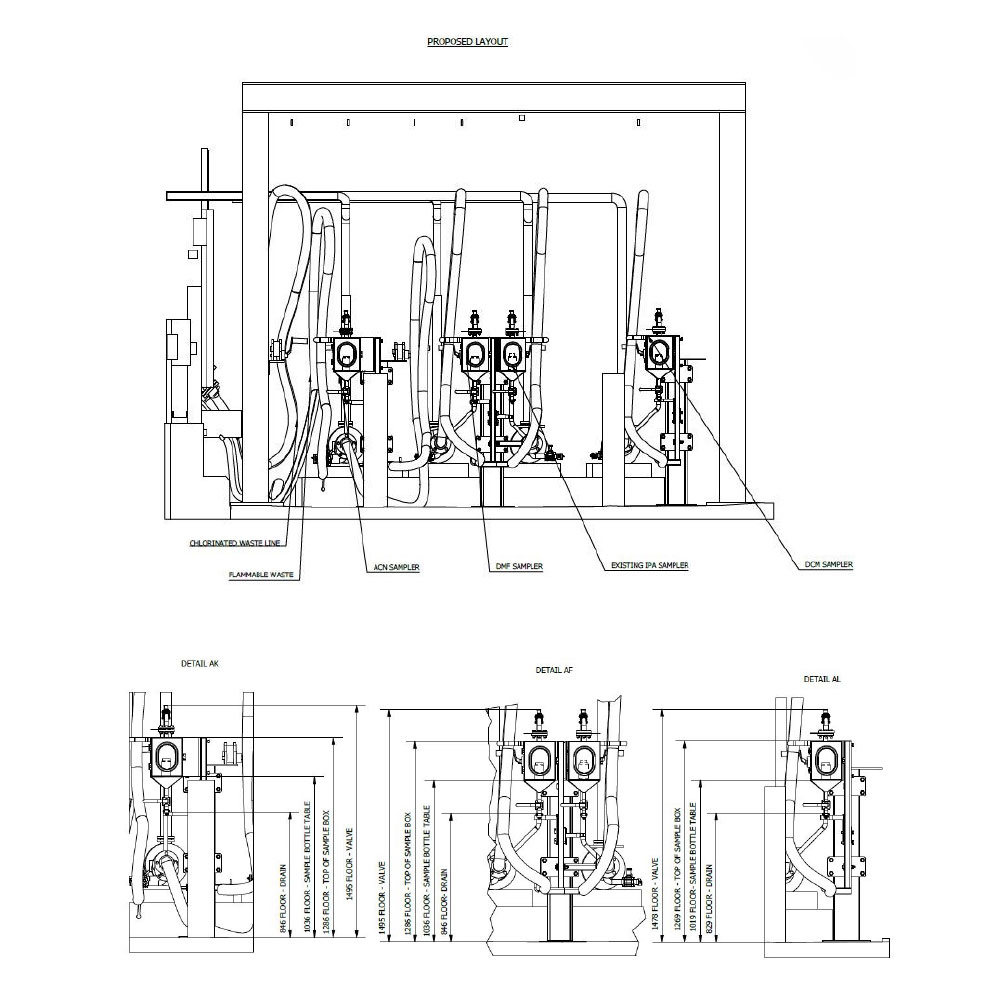

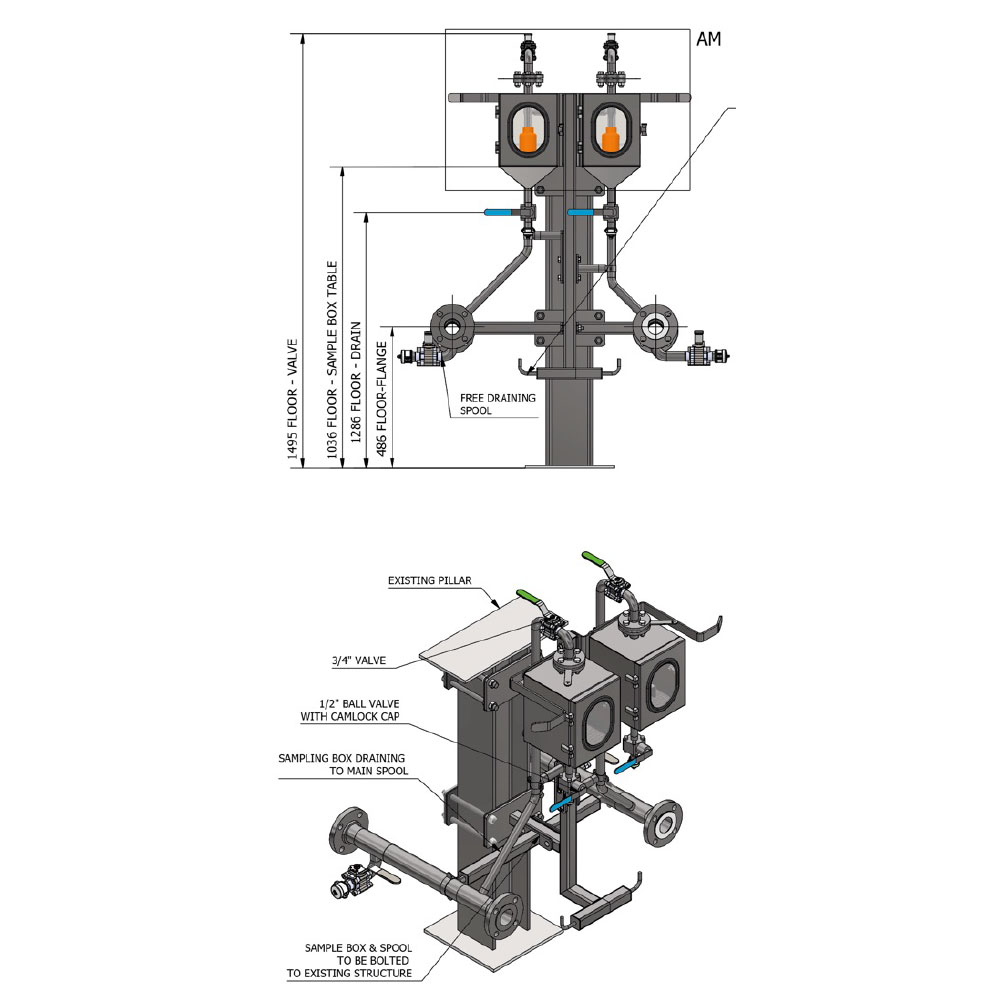

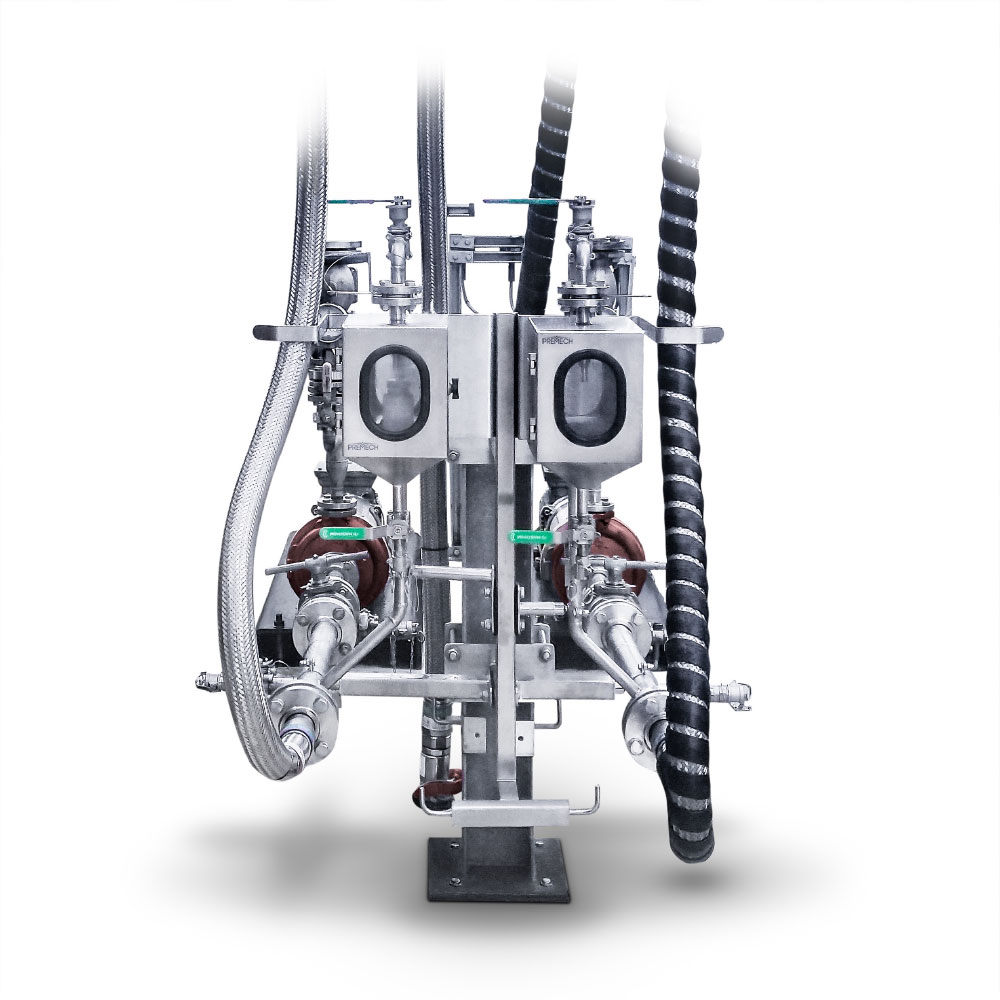

We designed a spool with flanged connections to accommodate the tanker and existing spool leading to the holding tanks. The design incorporated piping materials as specified by the client. The sampling system was required to be free draining once the tanker was finished unloading, leaving no product in the spool system.

A sampling box attached in line with the spools removed the need for the operator to climb onto the tanker. Ergonomic design with levers and valves made it easily accessible by operators, and all outlet flanges were closed by end caps to prevent accidental spills. Also, results from the site survey highlighted that an existing vertical pillar would need to be relocated.

Regular interaction between the client and engineer allowed the system to be manufactured swiftly. The design required only one connection to the tanker body. The operator can place a sampling bottle inside the sampling box and release a measured amount of product for sampling by opening a small valve. Once verified, the operator can open the remaining valves to unload the contents. The design allowed sampling to take place safely and quickly. Once installed, the system was SAT tested and a full ETOP was generated and handed over to the client allowing full traceability of materials and units used in the production.