Project Description

| Project Name | Discharge Chute Vent Line |

|---|---|

| Industry | Pharmaceutical |

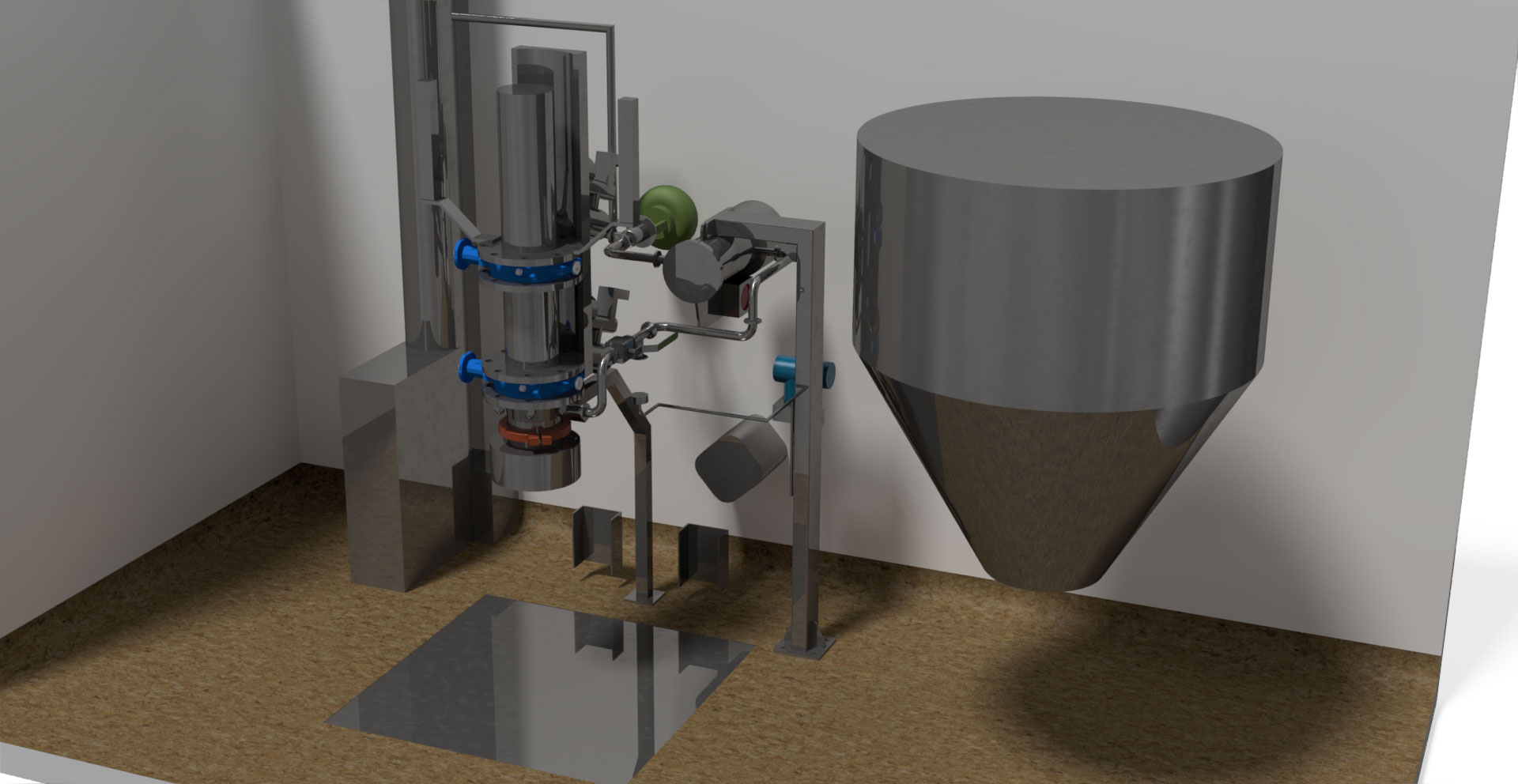

| Project Requirements | Design and fabricate pipework, discharge chute and support brackets to an existing dryer to allow for automated discharge of excess nitrogen from the process, while maintaining sufficient operator access. Site install to be completed within a 1-day downtime window. |

| Our Solution | We completed a full survey of the production area and produced a 3D model of the current equipment. Our team also produced 3D models for all valves, filters and actuators required for the new design. This 3D data was used to present concept layouts to our client’s engineers and operators. Once client approval was received, all fabrication was carried out off-site. Site install was completed within one day for minimal disruption to factory production |

Design and fabricate pipework, discharge chute and support brackets to an existing dryer to allow for automated discharge of excess nitrogen from the process, while maintaining sufficient operator access. Site install to be completed within a 1-day downtime window.

We completed a full survey of the production area and produced a 3D model of the current equipment. Our team also produced 3D models for all valves, filters and actuators required for the new design. This 3D data was used to present concept layouts to our client’s engineers and operators. Once client approval was received, all fabrication was carried out off-site. Site install was completed within one day for minimal disruption to factory production